Laser cleaning and rust removal, as long as the high beam of light can reach the place, there will be no dead corners. At present, environmental protection countries are paying more and more attention to the existing traditional methods. The choice of laser rust removal is green at anytime in anywhere. For large irregular areas, Shiying lasers can tailor the light source to suit you

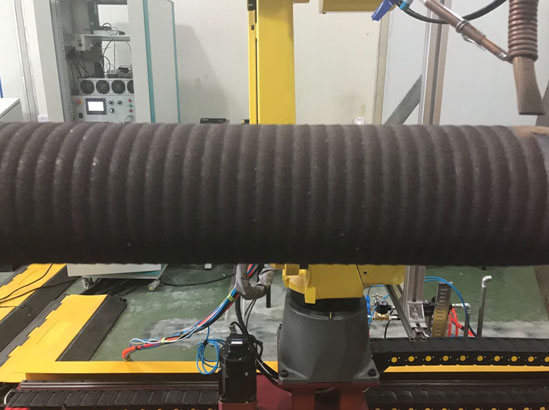

High cladding efficiency placing the selected coating material on the surface of the coated substrate with different filler methods and melting it, a thin layer of the substrate surface at the same time by laser irradiation quickly solidifies to form a very low dilution and with the substrate. The material becomes a metallurgically combined surface coating. Thereby it significantly improves the wear resistance, corrosion resistance, heat resistance and oxidation resistance of the surface of the base material.