The electronics industry

Electronic board oxide layer cleaning Electronic component joint cleaning before welding

More

Electronic board oxide layer cleaning Electronic component joint cleaning before welding

More

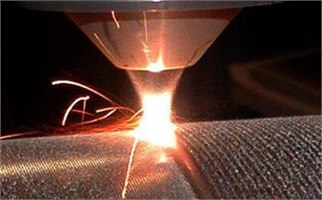

Laser de-rusting of steel surface; Laser de-rusting of Cold Rolled Sheet Surface

More

Laser cleaning of galvanized sheet before welding; Laser cleaning of aluminum alloy before and after welding

More

Laser cleaning of stainless steel train manufacturing; Laser cleaning for aluminum alloy train manufacturing; Laser cleaning for rail transit equipment maintenance

More

Laser cleaning before and after welding in shipbuilding; Laser cleaning surface before painting; Ship maintenance

MoreWe specialize in custom production of laser cleaning machines (equipment) and laser descaling machines (equipment), which can provide a complete set of laser processing solutions and related supporting facilities for domestic and foreign customers. Laser cleaning products and solution can be provided for large and small enterprises according to customers' products. Our product-specific scanning control technology makes full use of the technical characteristics of pulsed laser's short pulse width and high peak value, which greatly improves the efficiency of cleaning operations while ensuring the cleaning effect. Our laser cleaning (rust removal equipment) is receiving more and more enterprises' attention and application.

If you want to know how much a laser cleaning machine (equipment) and laser descaling machine (equipment) cost, you are welcome to call or write to us!

Address: No. 1258, Fugang Road, Nanqiao Town, Fengxian District, Shanghai

Phone: +86-021-37111608

Email: syingxs@163.com

Hand-held laser welding machines need attention when welding metal materials. As long as they can be welded by traditional welding, laser welding machines can do it.

In modern industry, there is an increasing demand for efficient processing and/or electrical micro-connection of thin metal materials.

Fiber laser is a recognized power in many industries and manufacturing industries because of its throughput, reliability and low operating cost.