Hand-held laser welding machines need attention when welding metal materials. As long as they can be welded by traditional welding, laser welding machines can do it. Compared with the traditional welding method, the welding range is wider, such as non-ferrous and metallurgical metals can be hand-held laser welding. So, in terms of welding metal materials, what are the precautions when performing hand-held laser welding?

First of all, pay attention to carefully check whether the reflective lens of the shutter is clean, the contaminated lens will explode quickly during use. So far, the adjustment of the laser part is complete. Laser With the development of laser welding technology, the technology of laser welding machine is gradually mature and the application of the industry continues to grow. However, in the actual welding production process, various problems will arise due to various reasons. Therefore, how to control the appearance of these problems and how to solve these quality problems has become the most important part of the production and processing process. For products that can be processed, we analyze the causes based on welding phenomena. Generally speaking, there are two reasons for poor processing effect, processing material problems, and using laser welding machine to change materials for collection can effectively solve this type of problem. The second, the setting of technical parameters, requires continuous testing of the same part according to the products being welded, and a discussion based on the welding results that appear continuously.

High security, the welding tip is only effective when the switch is touched when it touches the metal, and the touch switch has body temperature sensing.

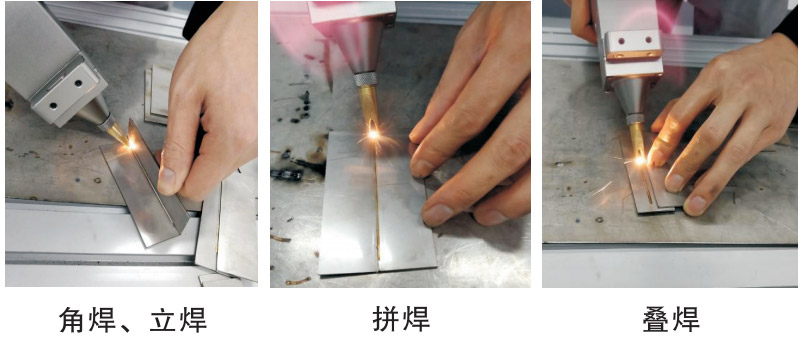

It can realize welding at any angle, and can weld various complex welded workpieces and large workpieces with irregular shapes. Realize welding at any angle.

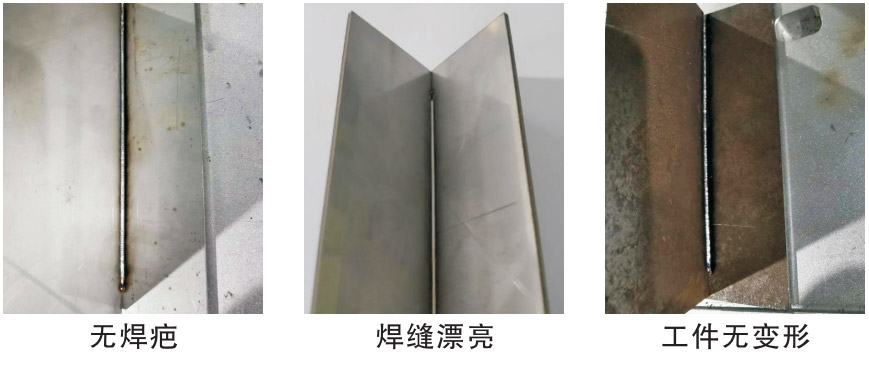

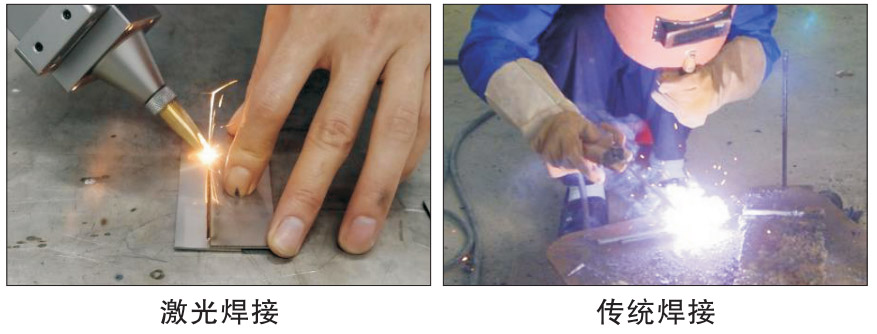

It can also maintain a clean and tidy working environment in the plant. Using friendly design suitable for laser welding to optimize the sheet metal production process. Compared with traditional welding, laser welding has obvious advantages, but laser welding has higher requirements on the front processing accuracy of workpieces and fixtures. To fully utilize the advantages of laser welding, reduce production costs and provide production efficiency, it is necessary to optimize the entire sheet metal production process such as product design, laser cutting, stamping, bending and laser welding. We found in actual production that the cost of sheet metal products using laser welding technology, laser welding process is not the main determinant. Actual production experience proves that 70% of the cost of sheet metal products is determined by product design. To reduce production costs and improve welding efficiency, we must first start with product design. In the initial product design, the requirements of laser welding on the workpiece are taken into consideration, such as reducing the bending process in production, using laser cutting as much as possible, and adopting self-positioning design.

Difficulties of laser welding machine welding aluminum alloy

Aluminum alloy has the following characteristics: light weight, non-magnetic, good low temperature performance, good corrosion resistance, good formability, etc., so it is widely used in various welded structural products. Using aluminum alloy instead of steel plate material for welding, the structural weight can be reduced by more than half.

Aluminum alloy welding is prone to pores;

The expansion coefficient of the weld line is large, which is easy to cause welding deformation;

Aluminum alloy welding is prone to hot cracks;

Aluminum alloy welded joints are severely softened and have a low strength coefficient, which is also the biggest obstacle hindering the application of aluminum alloy;

The surface of the alloy is prone to produce a refractory oxide film (A12O3 has a melting point of 2060°C), which requires a high-power density welding process;

Aluminum alloy has a large thermal conductivity (about 4 times that of steel), and at the same welding speed, the heat input is 2 to 4 times larger than that of welded steel.

Therefore, the welding of aluminum alloy requires an efficient welding method with high energy density, low welding heat input, and high welding speed.

Tongfa laser energy negative feedback fiber laser welding machine is the industry's first-class "energy negative feedback technology". It uses energy fiber to transmit the 1064nm laser generated by the solid-state laser to the fiber through laser coupling technology, and then pass the laser in the fiber The output mirror acts on the surface of the workpiece to achieve the purpose of welding. The use of optical fiber to transmit laser light can make use of the flexibility of optical fiber, so that the laser can process the workpiece at any angle and realize multi-dimensional flexible processing. The optical fiber also has a homogenization effect on the laser energy, which can output the laser spot energy according to the shape of the laser, and homogenize the laser, so that the quality of the emitted laser beam is better and the welding quality is improved. Suitable for welding between various metals and aluminum alloy materials.

|